Process & Information

The Process

Initial external inspection and removal of ancillaries left on.

Dismantle transmission

Initial hot wash all components

Inspection of all parts

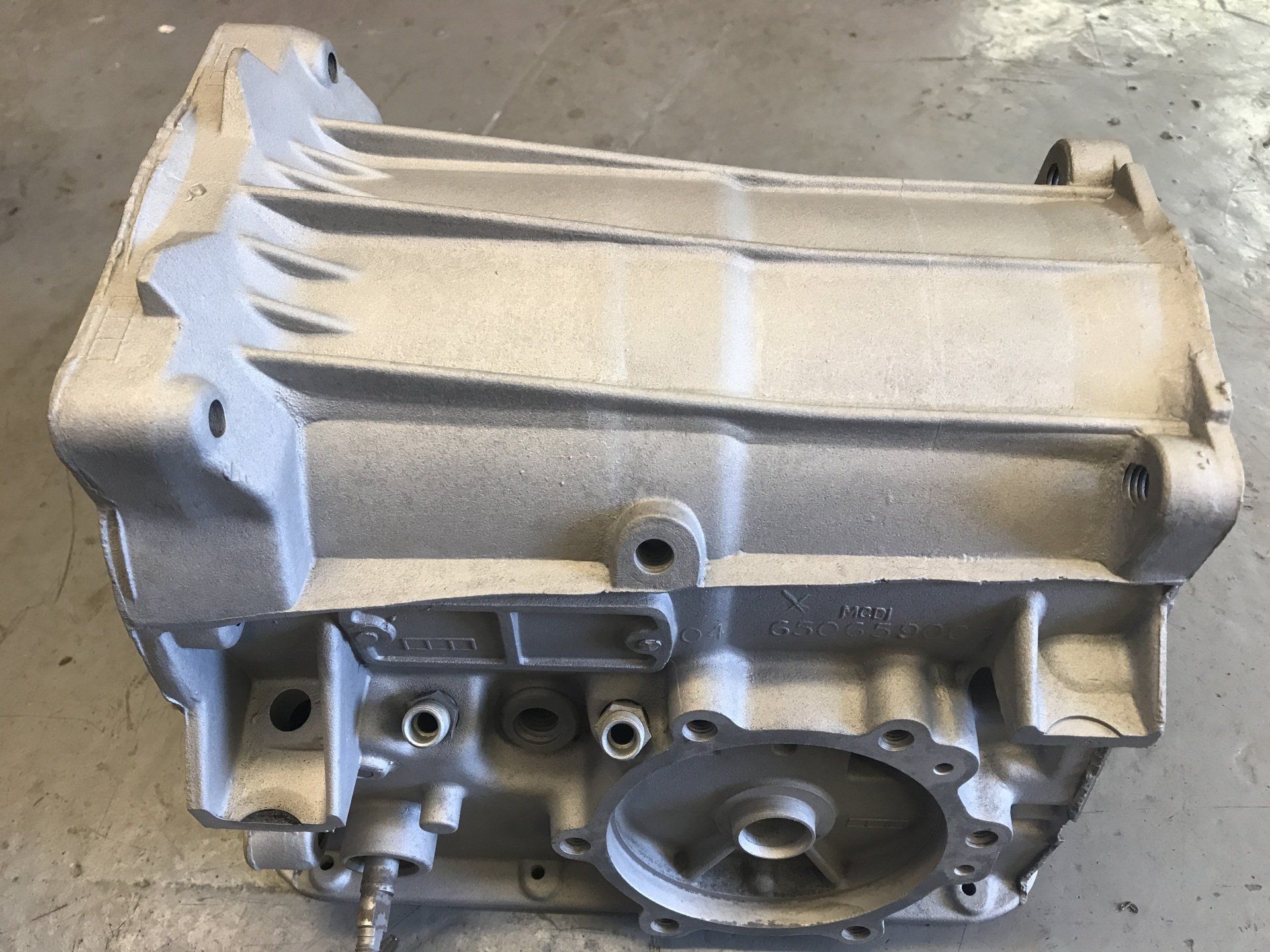

Casing and sumps soda blasted.

2nd hot wash of all components.

Ultrasonically cleaned.

Final inspection.

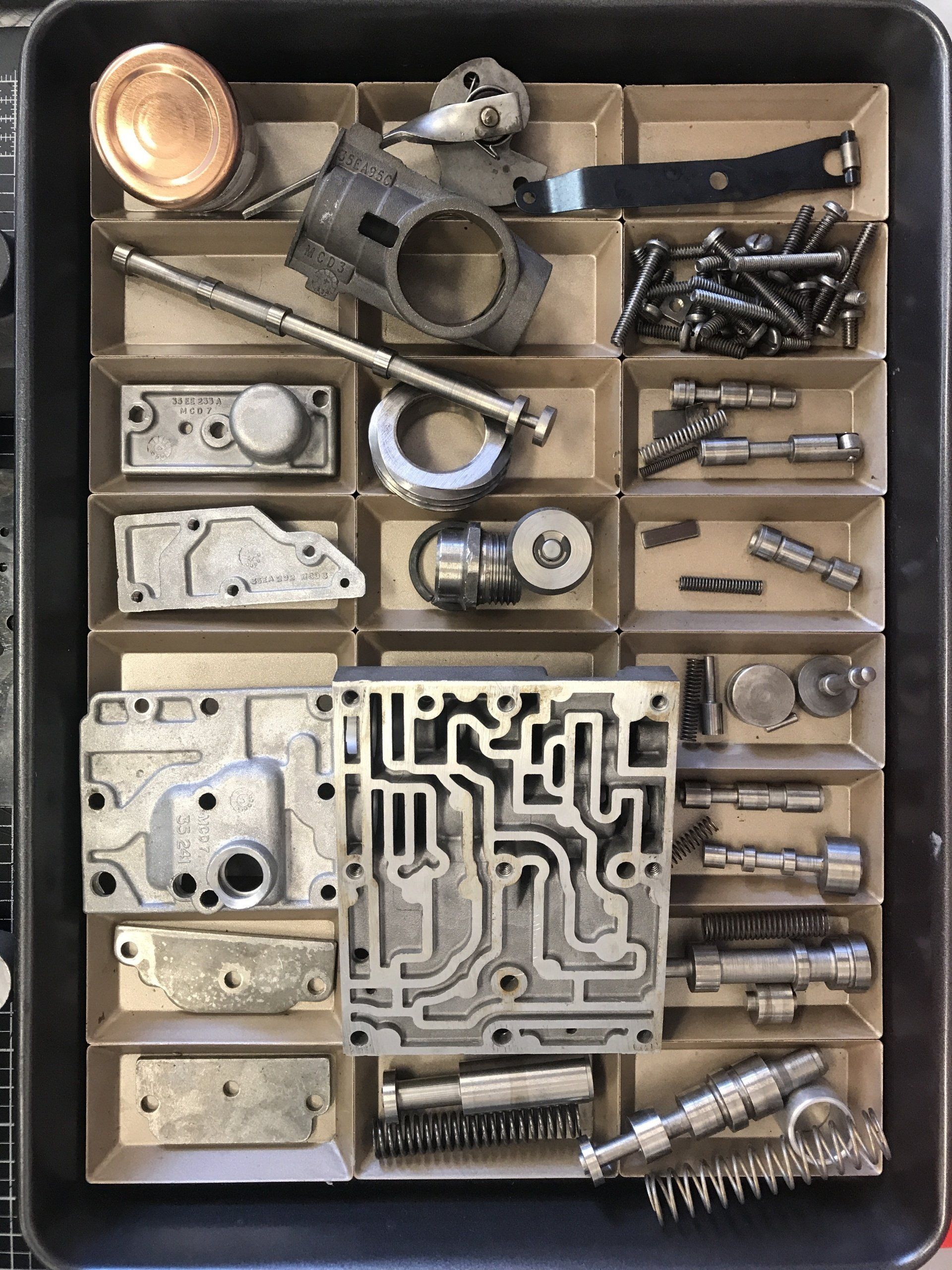

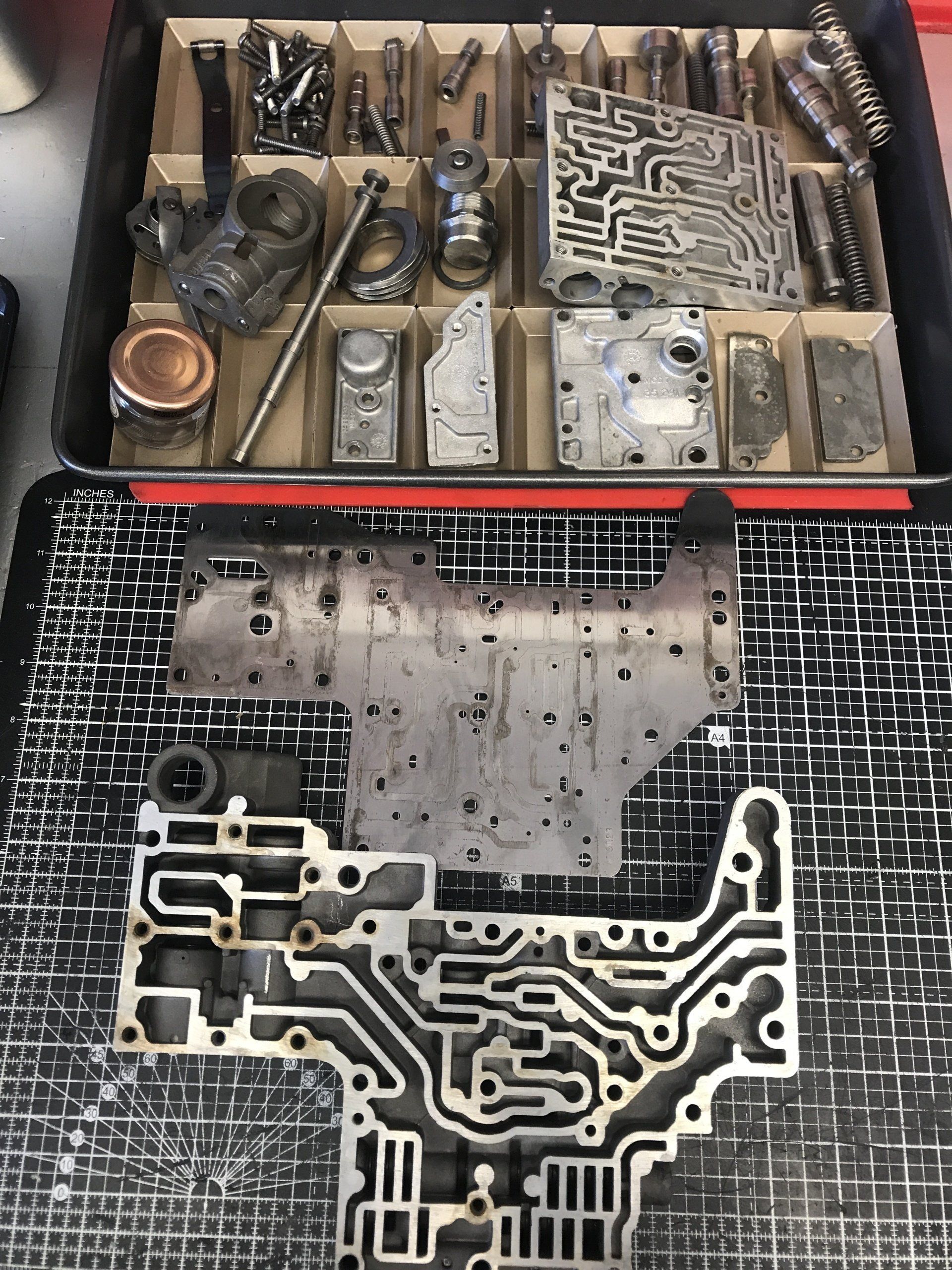

Valve body fully stripped, hot washed, inspected and ultrasonically cleaned before being rebuilt.

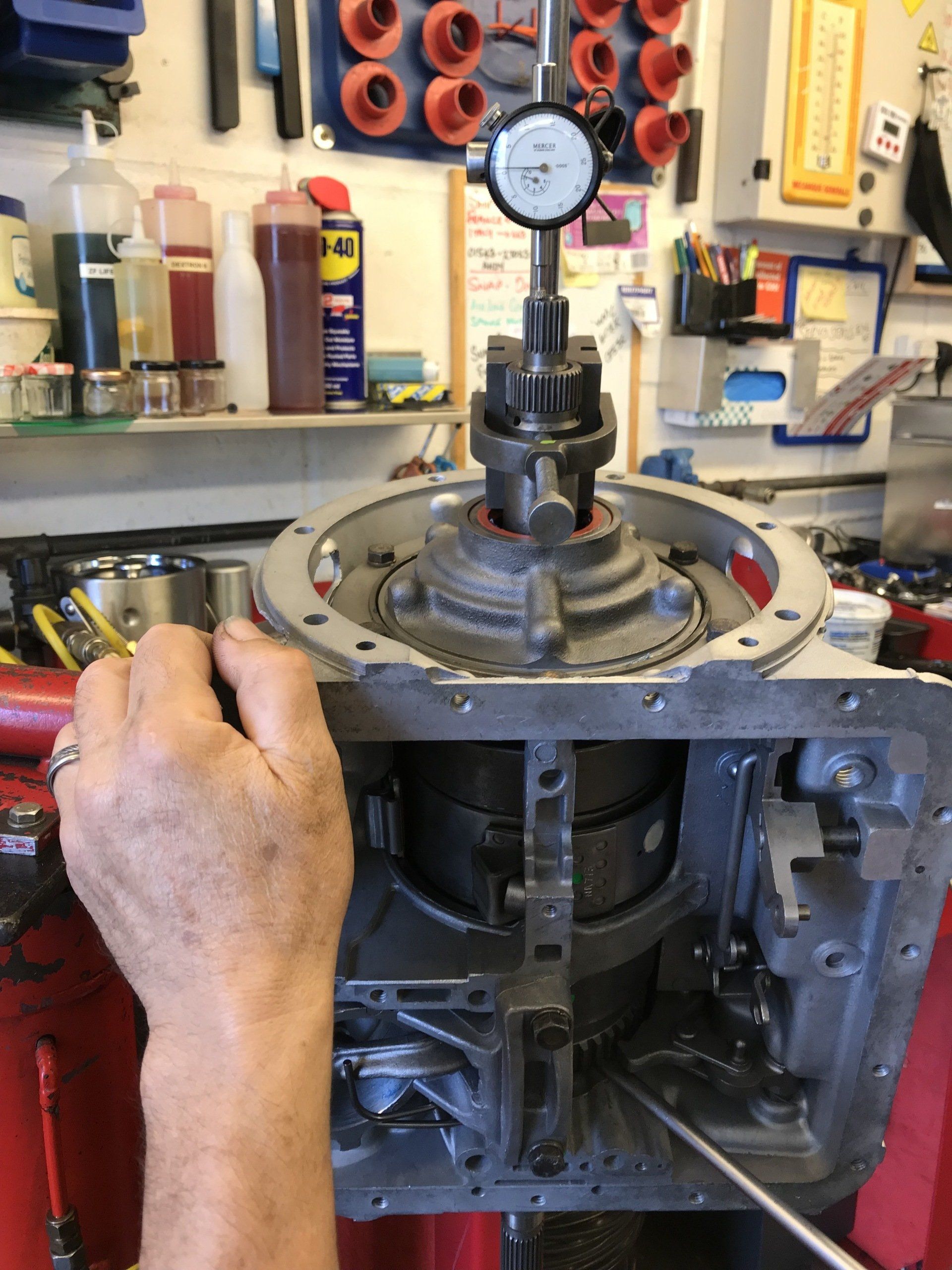

Torque converter rebuilt and balanced.

Final assembly.

Air test.

Hot run on test rig if applicable.

Stripped Component Process

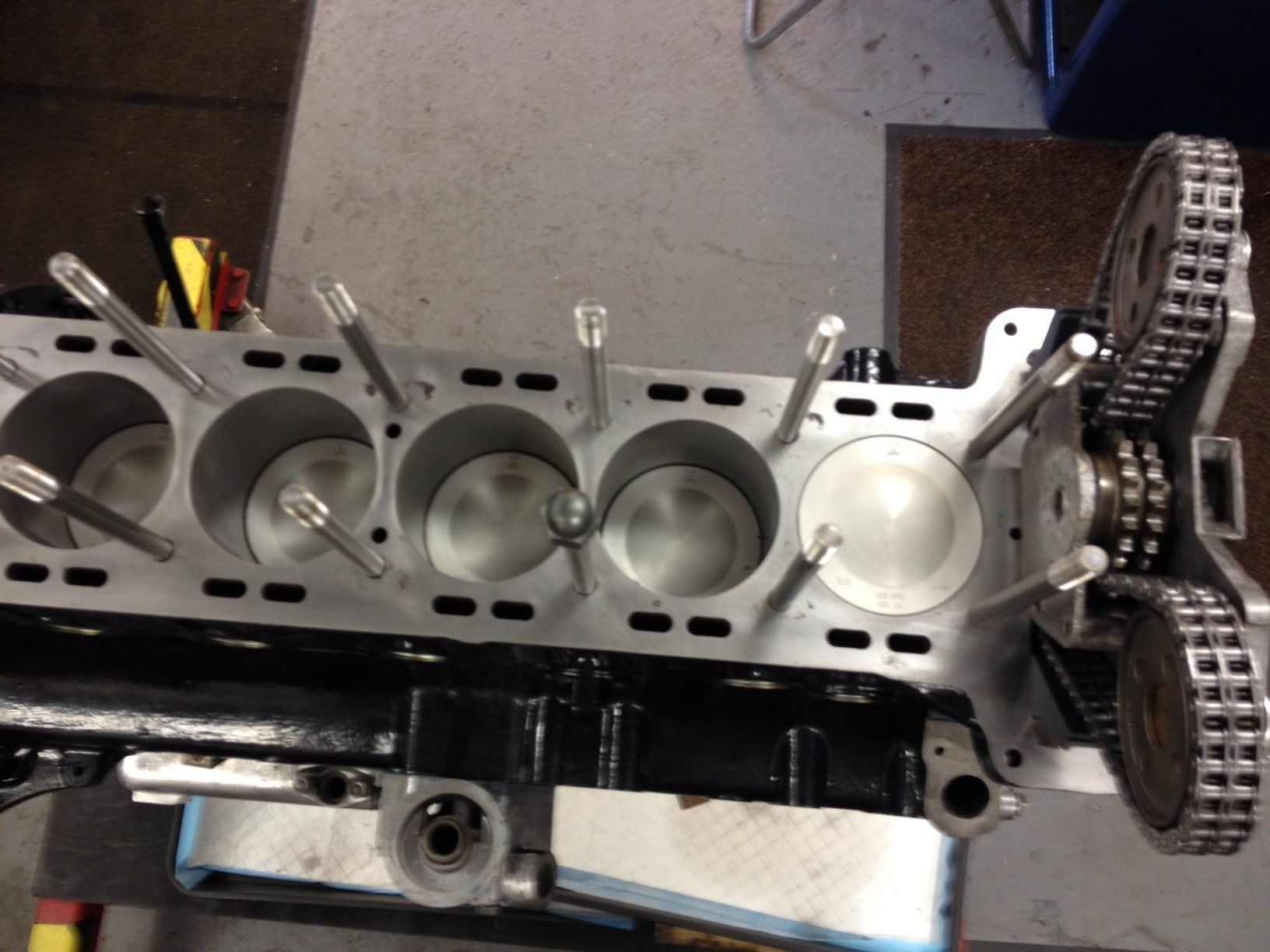

All gearboxes are fully disassembled and inspected for damage. They are then hot washed, checked and measured. We make sure that cases are blasted then re-washed, and all components are ultra-sonically cleaned in our hot tank.

Once all the cleaning is through, we re-inspect and measure the gearboxes again to ensure quality. Once assembled, automatic gearboxes are air tested and then hot run on our test bed.

Valve Body

Valve bodies are completely stripped and hot washed, then inspected and measured. We ensure they are ultra-sonically cleaned, re-assembled and air and vacuum tested.

Torque Converter

All torque converters are stripped, cleaned, checked and re-built to manufacturer’s tolerances.

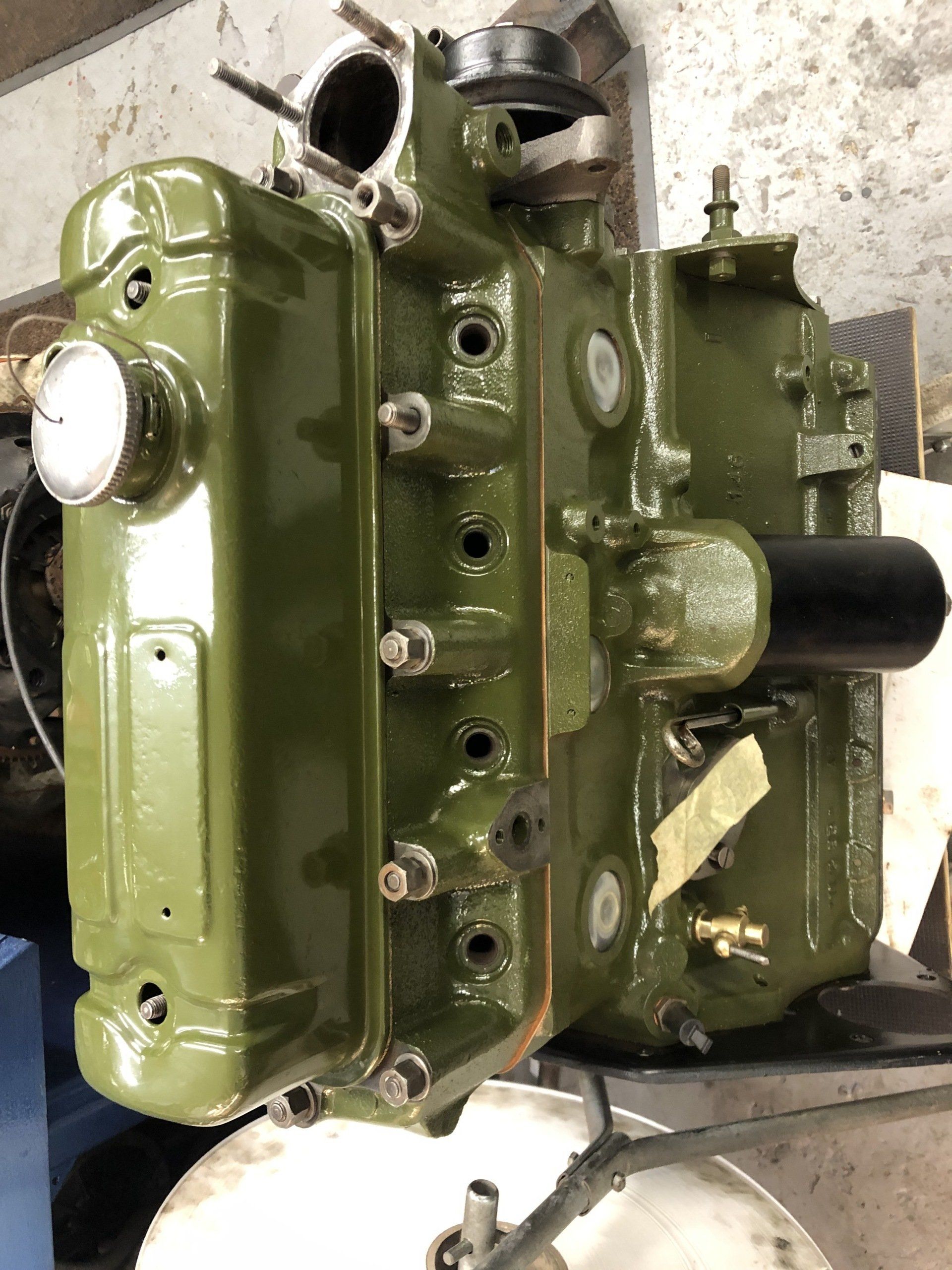

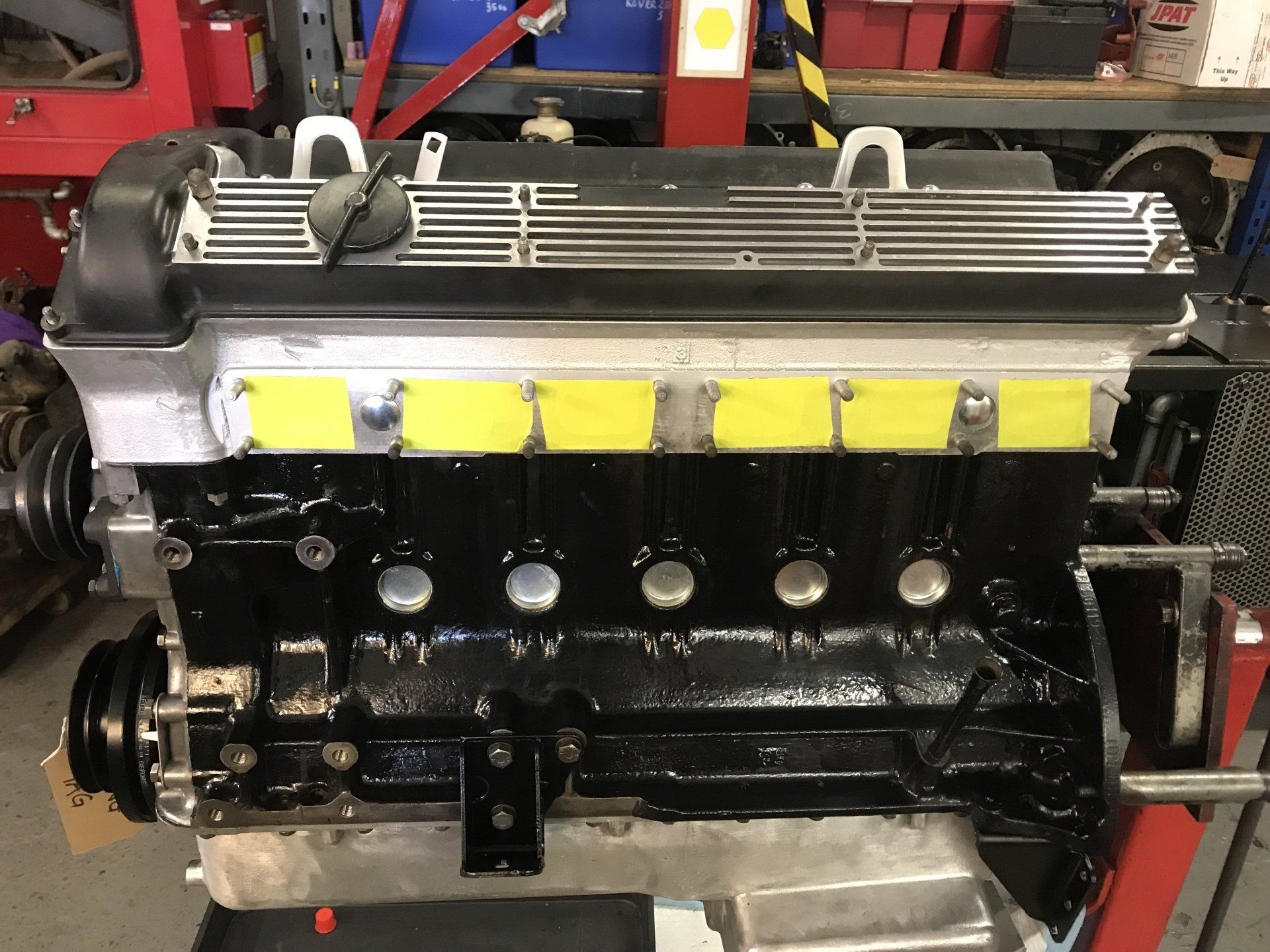

Special Projects

Here are some of the special projects we have worked on.

Get in Touch

If you have any questions, please get in touch with us for more information.